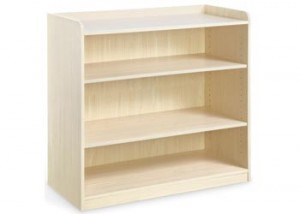

No home can have too much shelf space. This unit is a convenient tall design, which provides a lot of shelf room without taking up a great deal of floor space. It can be made from 16mrn or 18mm particleboard. If desired you can use particleboard with a bonded veneer finish which requires no further finishing. For best appearance, screws should be countersunk and the tops filled and sanded smooth before painting. Use long thread screws about one

gauge larger than you would normally use for timber. Dip the screws in glue before fastening and avoid over tightening them.

Cutting method.

- Cut 7 pieces each 225 x 300mm (from one sheet 900 x 300mm particleboard) for shelves and stabilisers.

- Cut 2 panels, 1500 x 300mm for sides

To assemble.

Using PVA adhesive and long thread particleboard screws, assemble the five shelf pieces between the side panels, leaving 300mm clearance between top and bottom shelves to fit stabilisers. Locate stabilisers (the two remaining 225 x 300mm pieces) in top and bottom openings, about two thirds back from the front edge. Screw and glue stabilisers into position.

Countersink screws, fill and sand smooth, fill edges ready for painting, or apply self-adhesive edging tape to the front edges. If using veneered particleboard, fill screw holes and colour to match surrounding surface.

Materials you’ll need:

- 2 pieces 1500 x 30Omm particleboard

- (16 or 18mm) a 2 pieces 900 x 30Omm (16 or 18mm) particleboard

- Long thread particle board screws

- P.V.A. adhesive

- Sandpaper

- Suitable filler

- Edging tape if required

Tools you’ll need:

- Screwdriver

- Metric rule

- Sharp panel saw (10 or 12 teeth per 25mm)